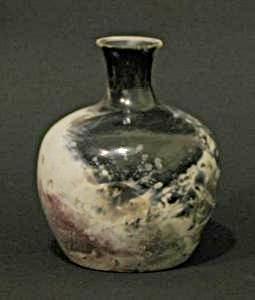

I wrote a while back that, for my first pit firing, I got some very nice fuming effects from a disemboweled Chore Boy type copper scrubber; but I was unable to reproduce the same effects ever since. Well, at the most recent firing I finally managed to get similar colors (and then some) with the same setup — and so here is the report…

I had seven pieces in this firing, two of which were intended as Chore Boy experiments. The first is a small pinched pot (figure 1 above) with two layers of packing materials, both very tightly wrapped around the pot:

- Chore Boy-type copper netting (one single layer)

- salted raffia (thin layer)

The feathery, wiggly lines in the deep red area apparently came from the copper netting that had started to disintegrate in that area. What’s unclear, however, is whether the larger, solid, and brighter red area to the right also came from the same. Or maybe it came from the admittedly plentiful copper carb in the pit instead?